CNC Corner Cleaning Machines

CNC Corner Cleaning Machines CNC Corner Cleaning Machines,upvc window machines,aluminium machines,upvc window

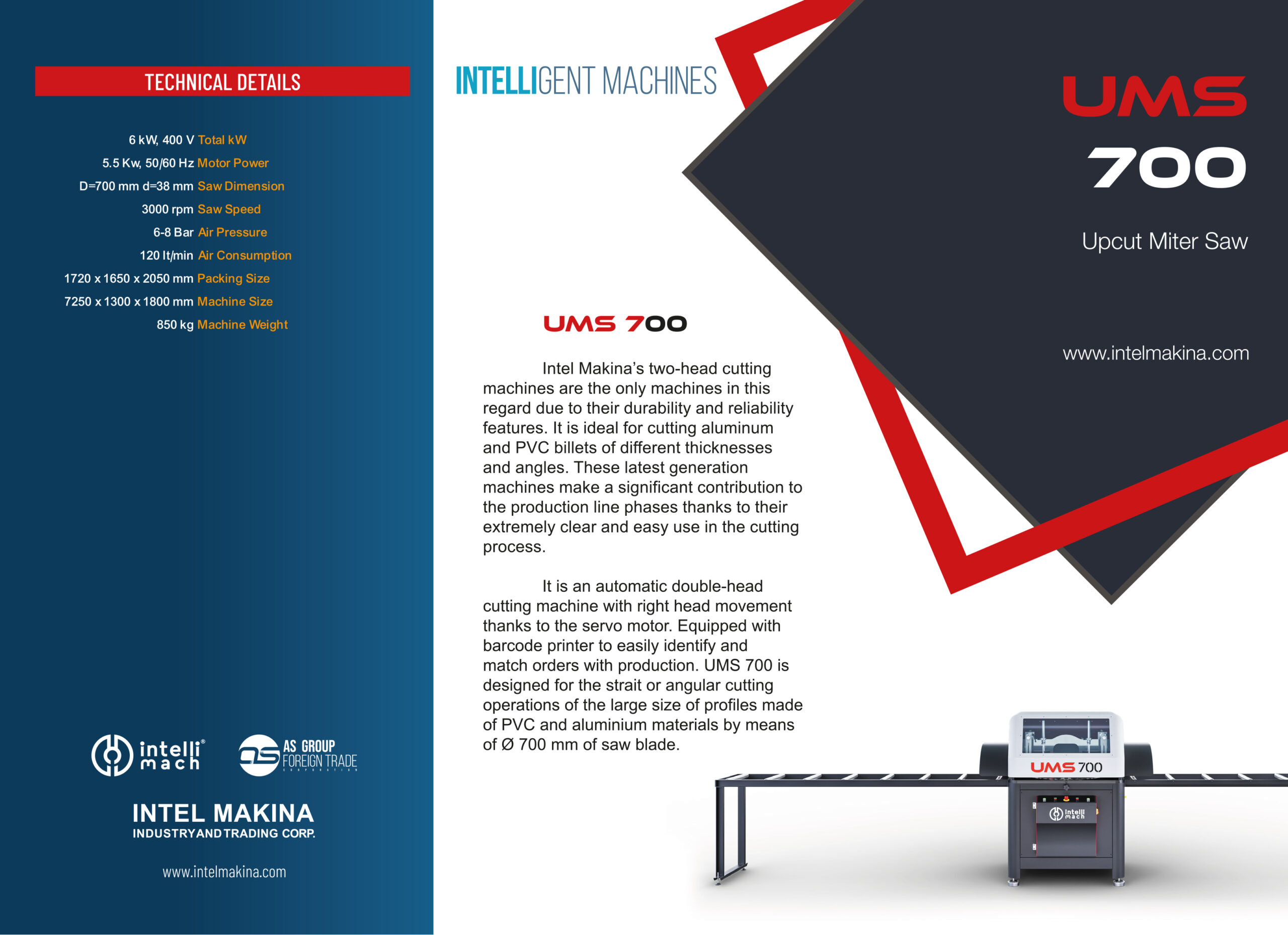

Upcut Miter Saw 700

Upcut Miter Saw 700 Intel Makina’s two-head cutting machines are the only machines in this regard due to their durability and reliability features. It is ideal for cutting aluminum and PVC billets of different thicknesses and angles. These latest generation machines make a significant contribution to the production line phases thanks to their extremely clear […]

uPvc Profile Machining and Cutting Center

uPvc Profile Machining and Cutting Center Pvc Profile Machining and Cutting Center – SIRIUS D550 Sirius D550 All sawing, milling, drilling and marking operations on PVC profiles are gathered in one machine controlled by a computer. Intel Makina’s Pvc Profile Machining and Cutting Center are the only machines in this regard due to their durability andreliability […]

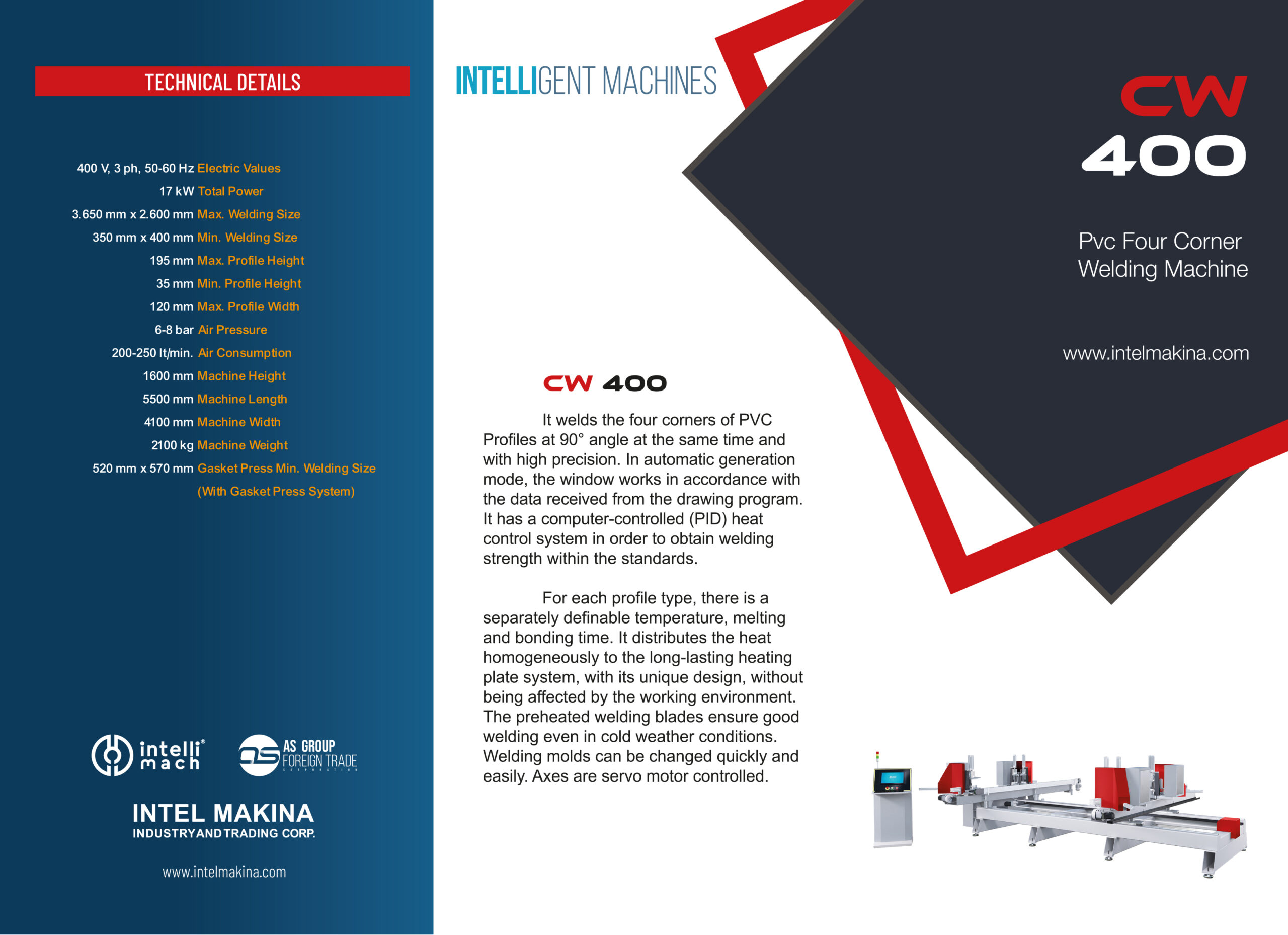

uPvc Four Corner Welding Machine

uPvc Four Corner Welding Machine Pvc Four Corner Welding Machine It welds the four corners of PVC Profiles at 90° angle at the same time and with high precision. In automatic generation mode, the window works in accordance with the data received from the drawing program. It has a computer-controlled (PID) heat control system in order to […]

Double Head Cutting Machine 600 mm Servo Angled

Double Head Cutting Machine 600 mm Servo Angled Double Head Cutting Machine 600 mm Servo Angled Intel Makina’s two-head cutting machines are the only machines in this regard due to their durability and reliability features. It is ideal for cutting aluminum and PVC billets of different thicknesses and angles.These latest generation machines make a significant […]

Alu Corner Crimping Machine

Alu Corner Crimping Machine Intel Makina’s Aluminum Corner Crimping Machines are the only machines in this regard due to their durability and reliability features. It is ideal for corner pressing of aluminum profiles of various thicknesses and angles. These latest generation machines make a significant contribution to the production line phases thanks to their […]

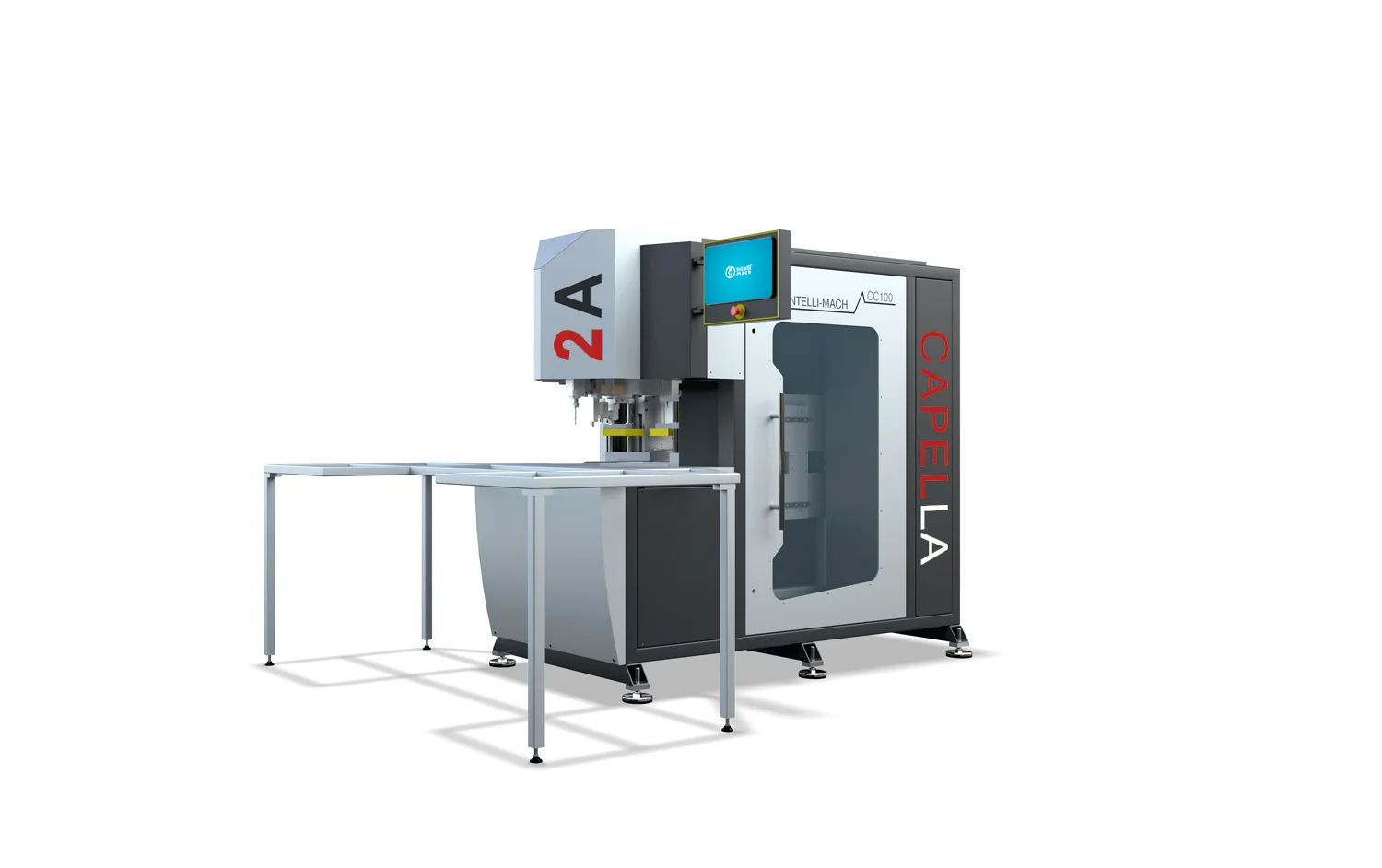

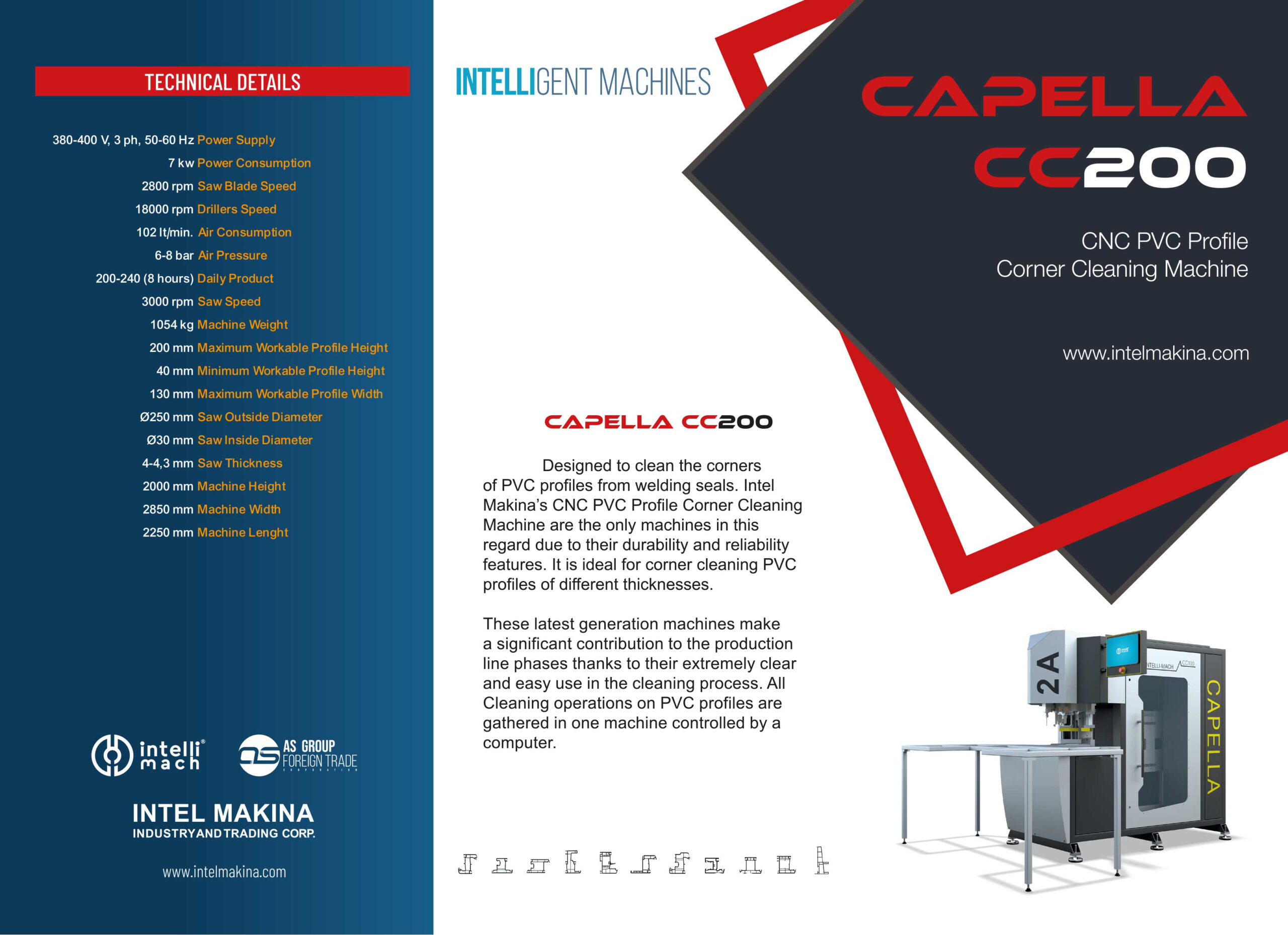

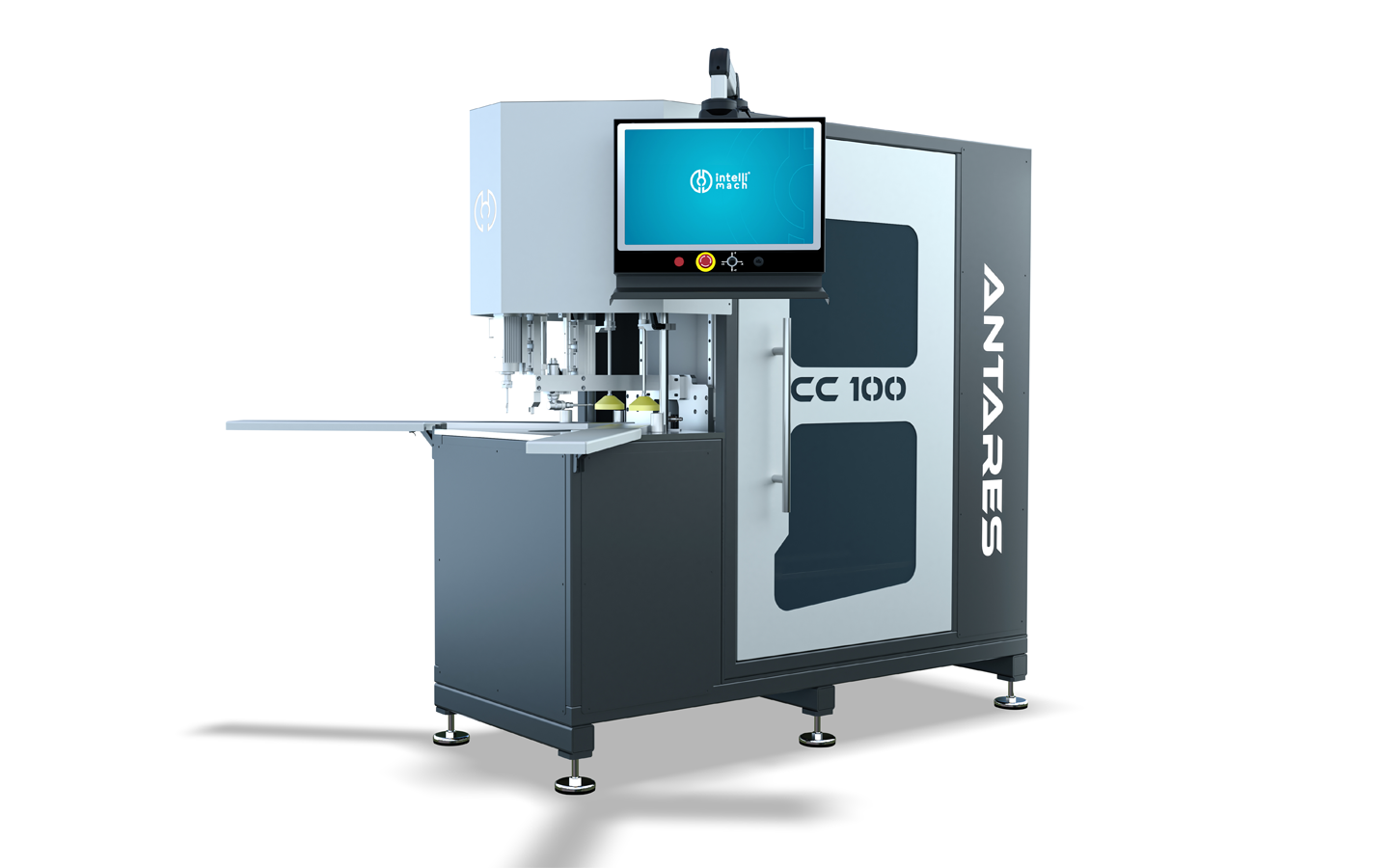

CNC uPVC Profile Corner Cleaning Machine

CNC uPVC Profile Corner Cleaning Machine Designed to clean the corners of PVC profiles from welding seals. Intel Makina’s CNC PVC Profile Corner Cleaning Machine are the only machines in this regard due to their durability and reliability features. It is ideal for corner cleaning PVC profiles of different thicknesses. These latest generation machines make […]

Alüminyum ve Pvc Profil Kesim Makinaları

Alüminyum Profil Kesme Makinası Alüminyum profil kesme makinası, UPVC kapı penceresi, alüminyum kapı penceresi üretmek için çok önemli bir ekipmandır. Aynı anda bir pencere çerçevesi parçasını kesebilen iki kafa vardır. Ölçüm sistemleri Profil kesme makinelerini kullanırken ölçüm doğruluğu çok önemlidir. Kesimdeki en ufak bir hata bile projeye zarar verecektir. Doğru ölçüye göre kesim yapan ölçüm […]

Cnc Köşe Temizleme Makinaları

CNC köşe temizleme makinası, genellikle pvc, alüminyum profil gibi malzemeler üzerinde kullanılan bir CNC (Bilgisayar Numaralı Kontrol) makinası türüdür. Bu makinalar, özellikle pvc kapı ve pencere, yapı endüstrisi ve alüminyum işleme gibi sektörlerde yaygın olarak kullanılır. İşlevi, malzemenin köşe ve kenarlarını düzgünleştirmek, şekillendirmek veya kesmek için tasarlanmıştır. Bu makinalar genellikle bir CNC kontrol ünitesi tarafından […]

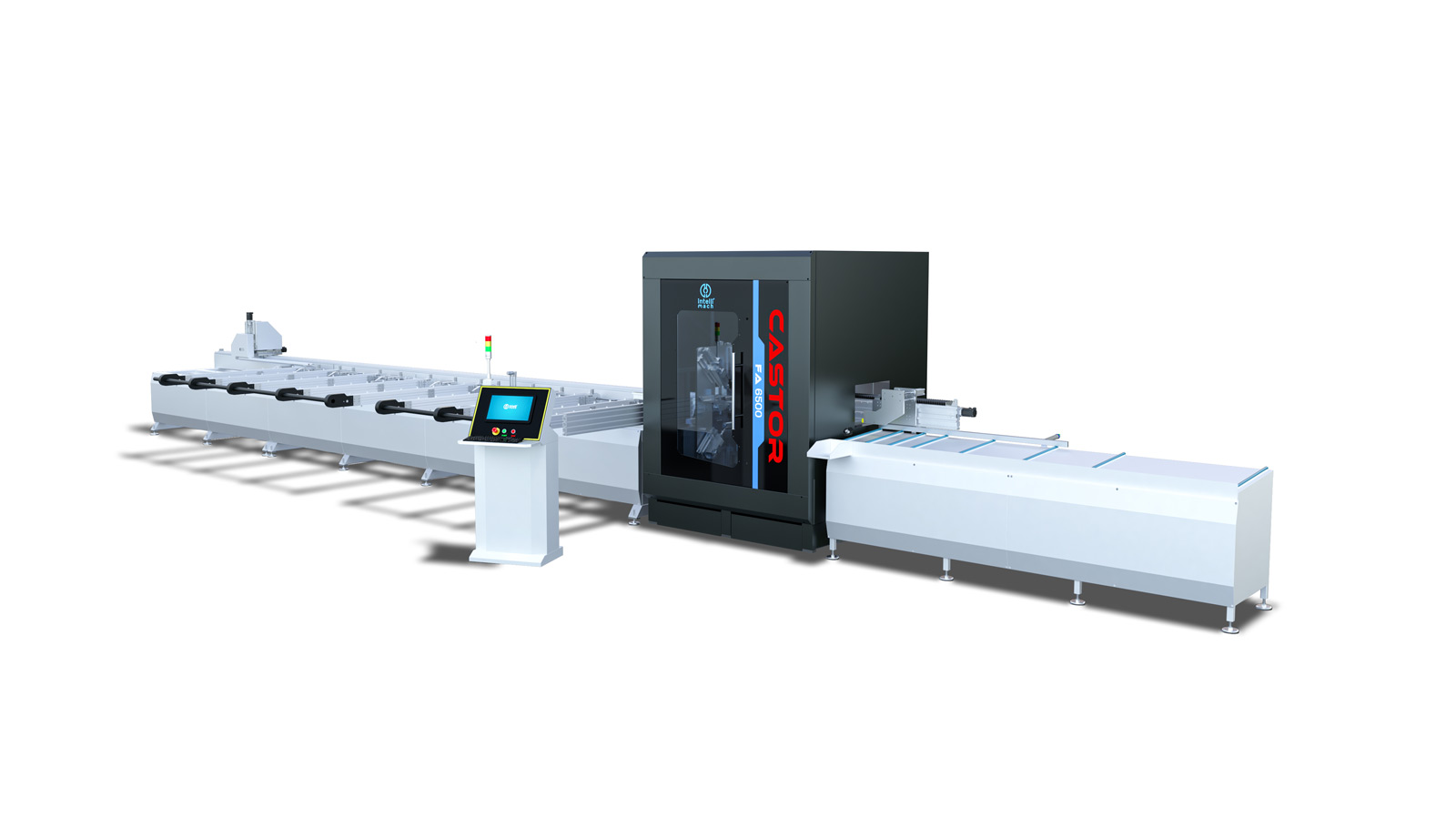

Pvc Profile Machining and Cutting Center CASTOR FA 6500

Pvc Profile Machiningand Cutting CenterCASTOR FA 6500 Castor FA 6500 All sawing, milling, drilling and marking operations on PVC profiles are gathered in one machine controlled by a computer. Control Panel Automatic cutting in all angles between 30° and 150° with accuracy of 0,1° by means of servo motors Stacking of 9 profiles (max 7 m length) Industrial PC with Windows […]