INTEL MAKINA PRODUCING

SOLUTIONS COVERING

ALL PROCESSES

IN UPVC AND ALUMINUM AUTOMATION

SINCE

1971

High-value, environmentally friendly and energy-saving technological machines

WE PRODUCE SMART MACHINES

FOR THE PVC ALUMINUM SECTOR WITH INDUSTRY 4.0 TECHNOLOGY

It incorporated Intel Makina A.Ş. Producing solutions covering all processes in uPvc and Aluminum automation. Intel Makina A.Ş., to increase the working efficiency of factories and the comfort of employees continues to improve its superior technology day by day.

- Advanced products

- Environmental and energy saving

- Sustainable growth

COMPLETE SOLUTIONS

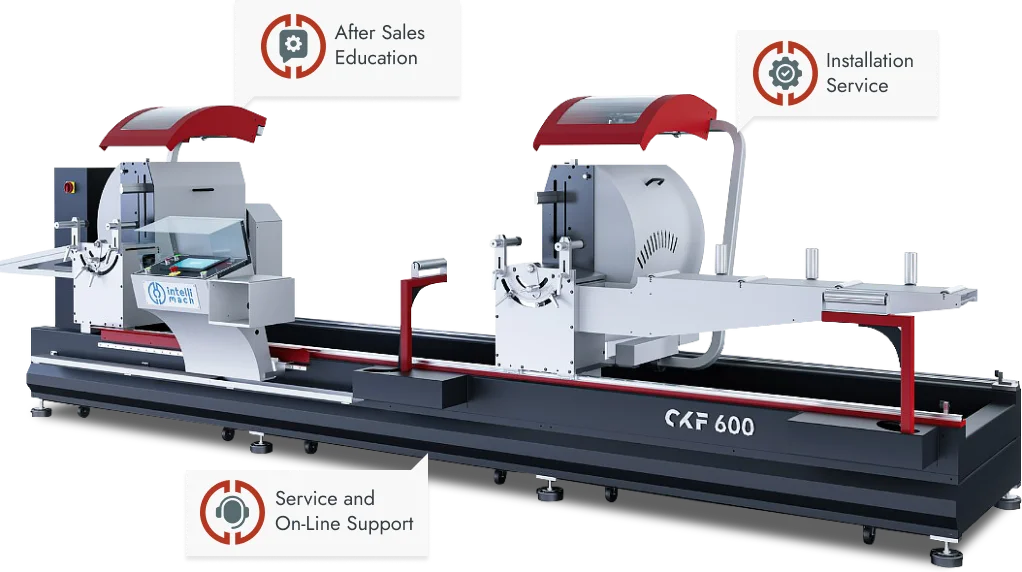

AFTER SALES EDUCATION, INSTALLATION SERVICE AND ON-SITE SUPPORT

We offer technical service and spare parts service with our expert and experienced technical team. We complete the solution of all your technical problems in the shortest time and in the most accurate way.

WE PRODUCE SMART MACHINES

INTEL MAKINA A.S. USES RESOURCES EFFECTIVELY AND EFFICIENTLY, ON THE WAY TO SUSTAINABLE GROWTH TAKES FIRM STEPS FORWARD TO THE FUTURE

FAQS

FREQUENTLY ASKED QUESTIONS

If you can’t find the answer you are looking for here, please contact us.

What is the difference between Aluminum Profile Cutting Machine and uPvc Profile Cutting Machine?

The body structures may be the same between the 2 machines, but additional features such as saw selection and cooling system hdyroheck speed adjustment are required in aluminum cutting machines.

Is it important for PVC profiles to break in the middle after welding?

Yes, the most important difference is that it should not break from the welded area after welding. The required profile should not break from the welding area, but also from the PVC profile. And it should be broken at a minimum weight of 350 kg.

What is the most important point in the Aluminum Profile corner press?

The most important feature is that the pressing blades reach the profile at the same time during the pressing phase.

What is the difference between machines equipped with Industrial 4.0 Technology?

Industrial PC is used in these machines and provides technical support and updates by connecting remotely.

How is the saw selection made in Cutting Machines?

Negative gear: It is especially suitable for lever machines for cutting sheet metal Aluminum Profile pipes and bars with different material thicknesses.

Positive gear: Recommended in automatic machines for cutting Aluminum Profile pipes and bars with material thickness over 5 mm

Are Upvc welding molds different?

Welding support mold can be produced from aluminum (6013-6053) and in some cases steel (1040) as raw materials. Production method and design may vary according to customer requests and needs.

Welding support molds are manufactured according to single head machine, double head machine and four head machine. Mold designs vary depending on the machine brand used.

NEWS AND EVENTS

LATEST ARTICLES FROM INTEL MAKINA

Follow the latest articles about Intel Makina and sectoral news

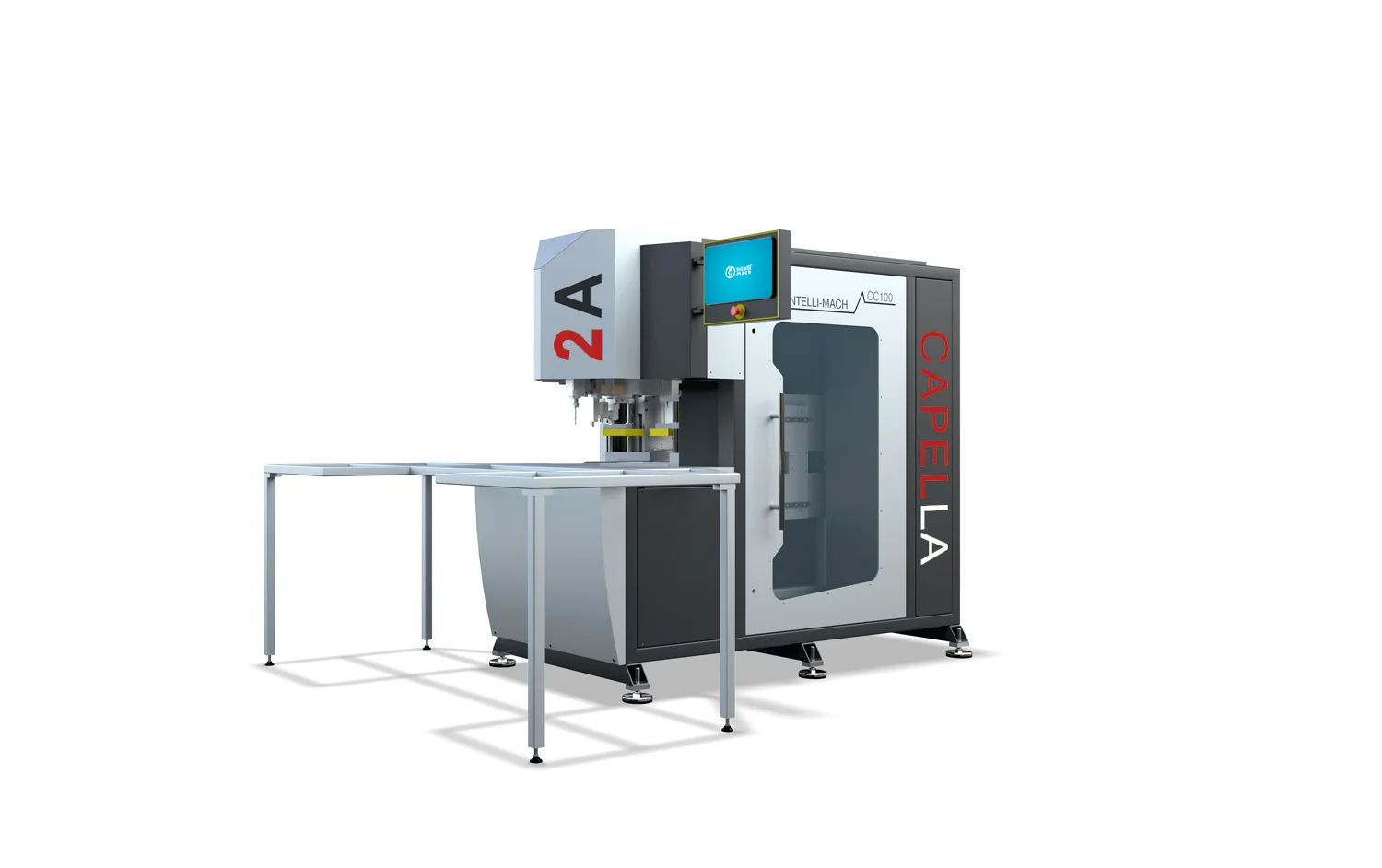

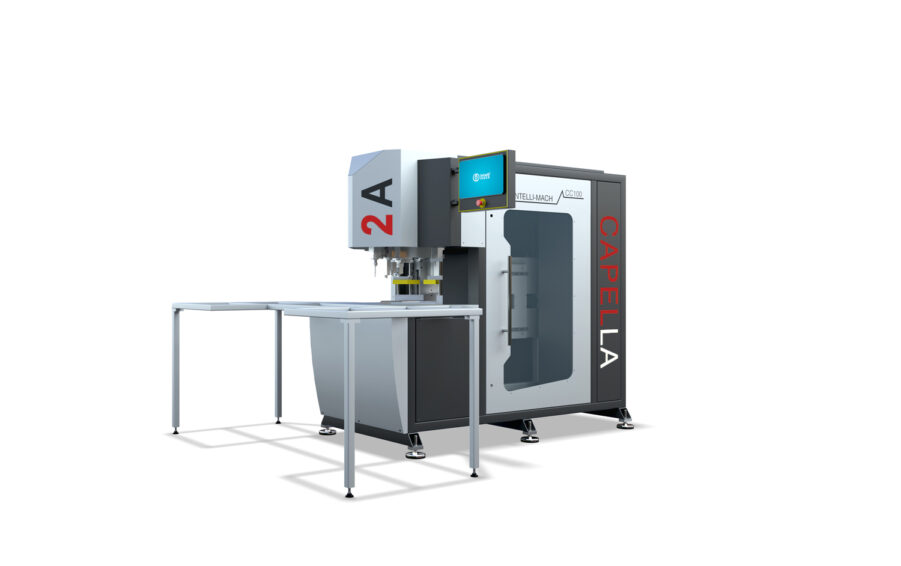

CNC Corner Cleaning Machines

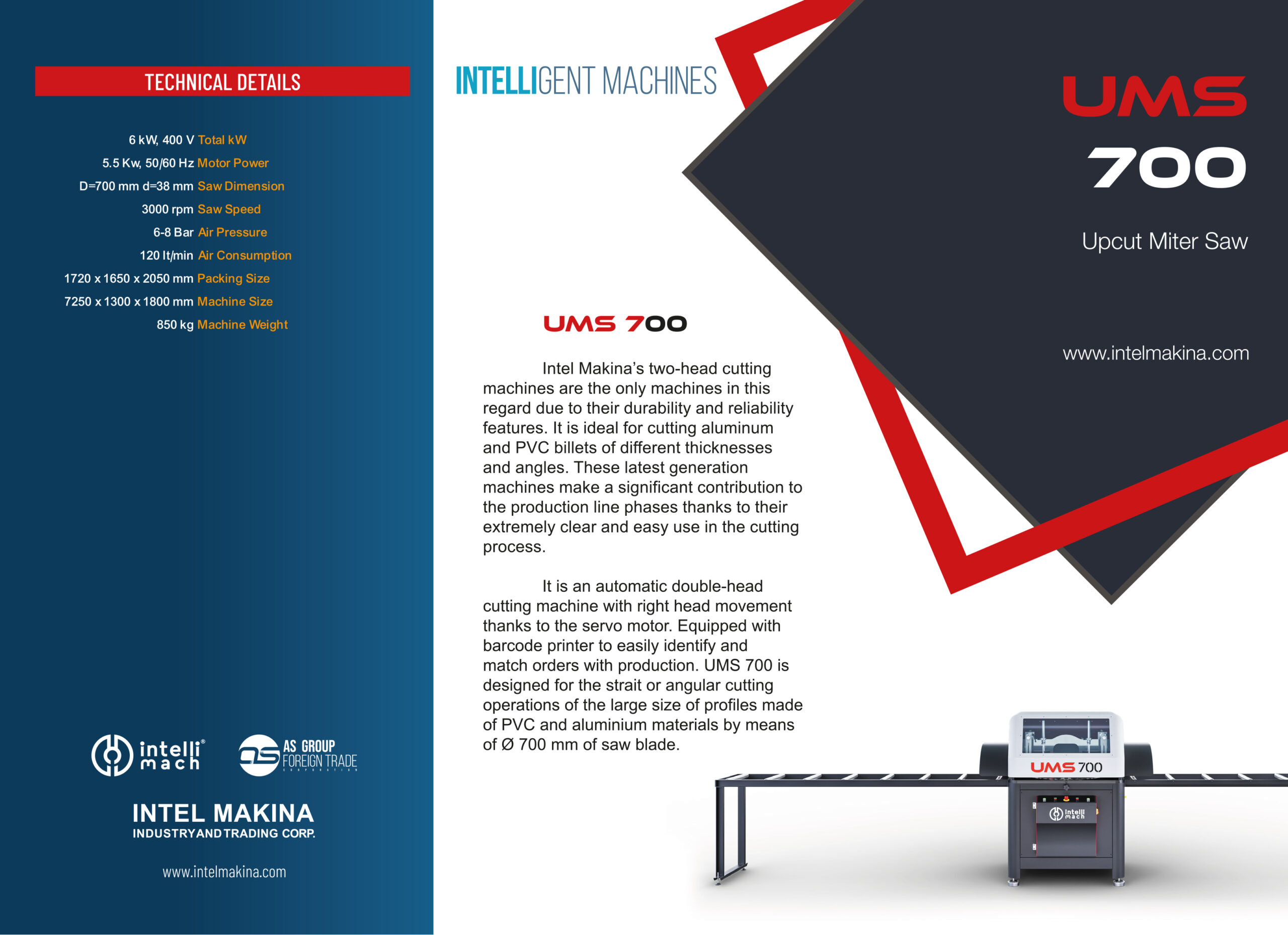

Upcut Miter Saw 700

SIRIUS D550

SIRIUS D550 CC 200

CC 200 CKF-550

CKF-550 CW 400

CW 400 CP 100

CP 100 CKF 600 S

CKF 600 S CKF 600 P

CKF 600 P