» Products » uPvc Profile Machining and Cutting Center

Pvc Profile Machining and Cutting Center – SIRIUS D550

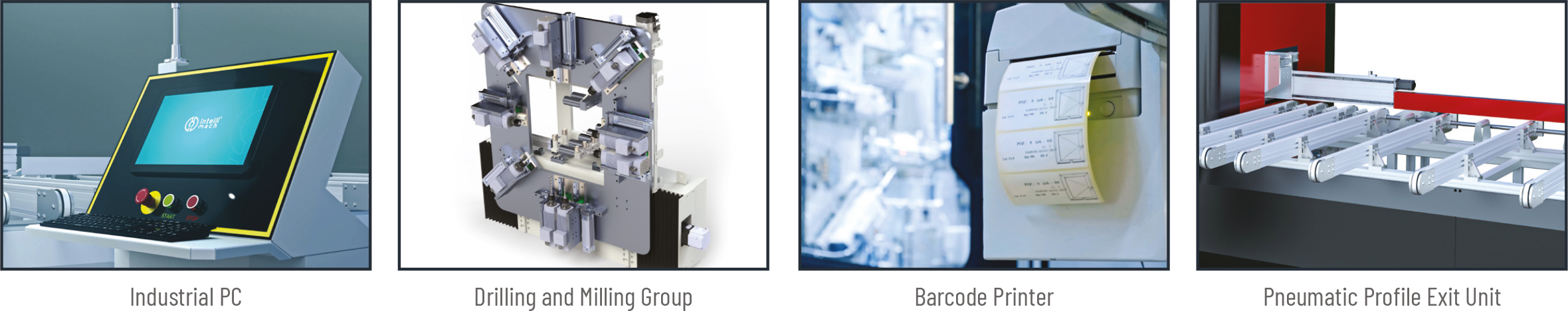

Sirius D550 All sawing, milling, drilling and marking operations on PVC profiles are gathered in one machine controlled by a computer.

Intel Makina’s Pvc Profile Machining and Cutting Center are the only machines in this regard due to their durability andreliability features. It is ideal for cutting aluminum and PVC profiles of different thicknesses and angles. These latest generation machines make a significant contribution to the production line phases thanks to their extremely clear and easy use in the cutting process. SIRIUS D 550 All sawing, milling, drilling and marking operations on PVC profiles are gathered in one machine controlled by a computer.

CONTROL

PROFILE ENTRY UNIT

PROFILE EXIT UNIT

INDUSTRIAL LABEL PRINTER

There is no information about optional equipment Please contact us for your requests.

© 2024. All rights reserved. Intel Makina A.S. Design: Elnur Ahmadov