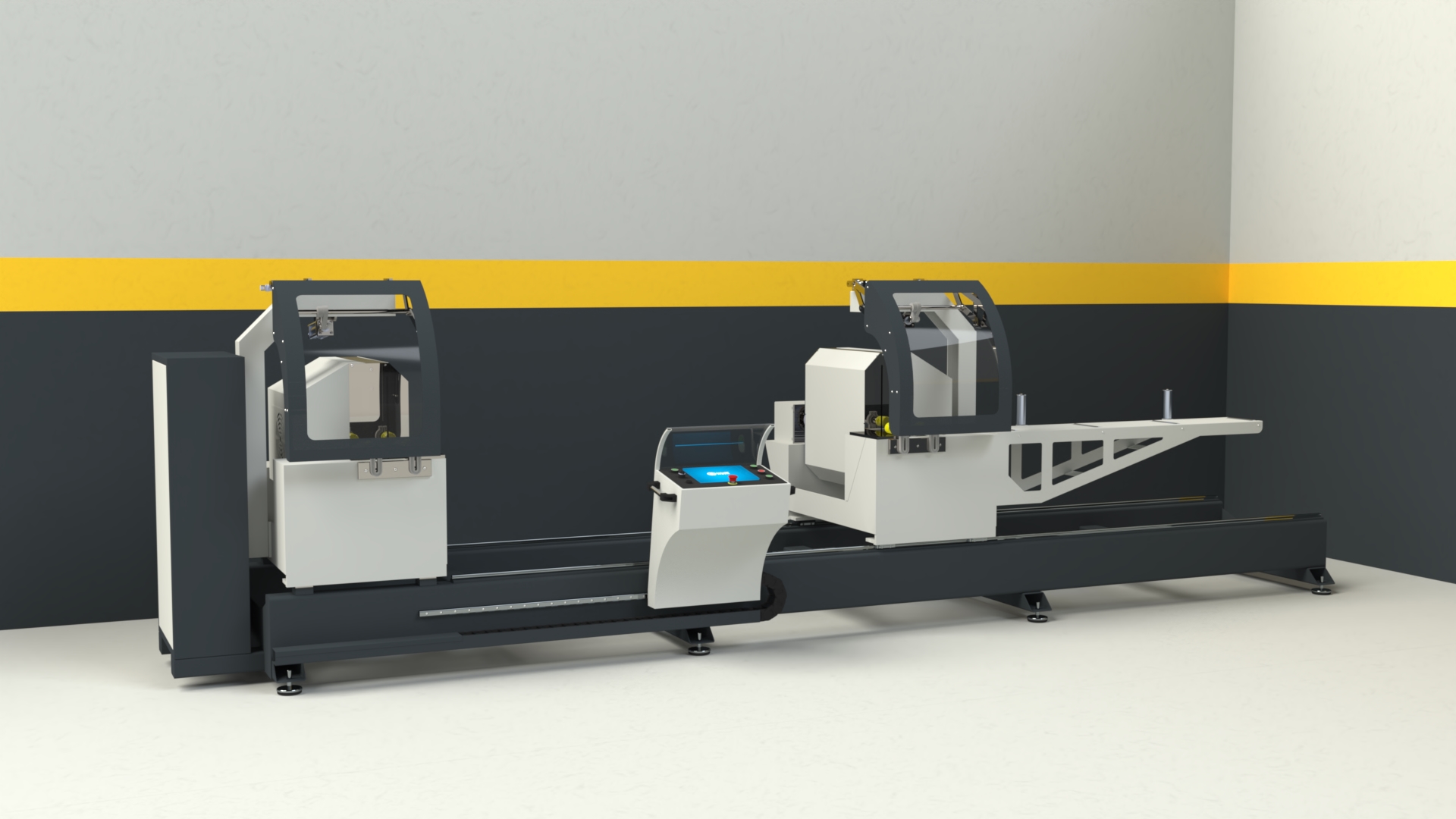

Double Head Cutting Machine 550 mm

Double Head Cutting Machine 550 mm Double Head Cutting Machine 550 mm High precision cutting of PVC and Aluminium profiles Strong construction, lineer rail and sliding-bearing system for precise length and angle. The saw heads tilt automatically for 45° and 90° cutting and easy manual fixation for Intermediate angles Easily adjustable blade cutting speed Profile […]

pvc window machinery

pvc window machinery When it comes to UPVC and aluminium window and door fabrication, the best equipment is made by İntelli Mach, a leading company. These machines support the fabrication of orangeries, conservatories, shop fronts and curtain walling. These machines are easy to use and maintain, provide accuracy and streamline traditionally labour-intensive processes. Read on […]

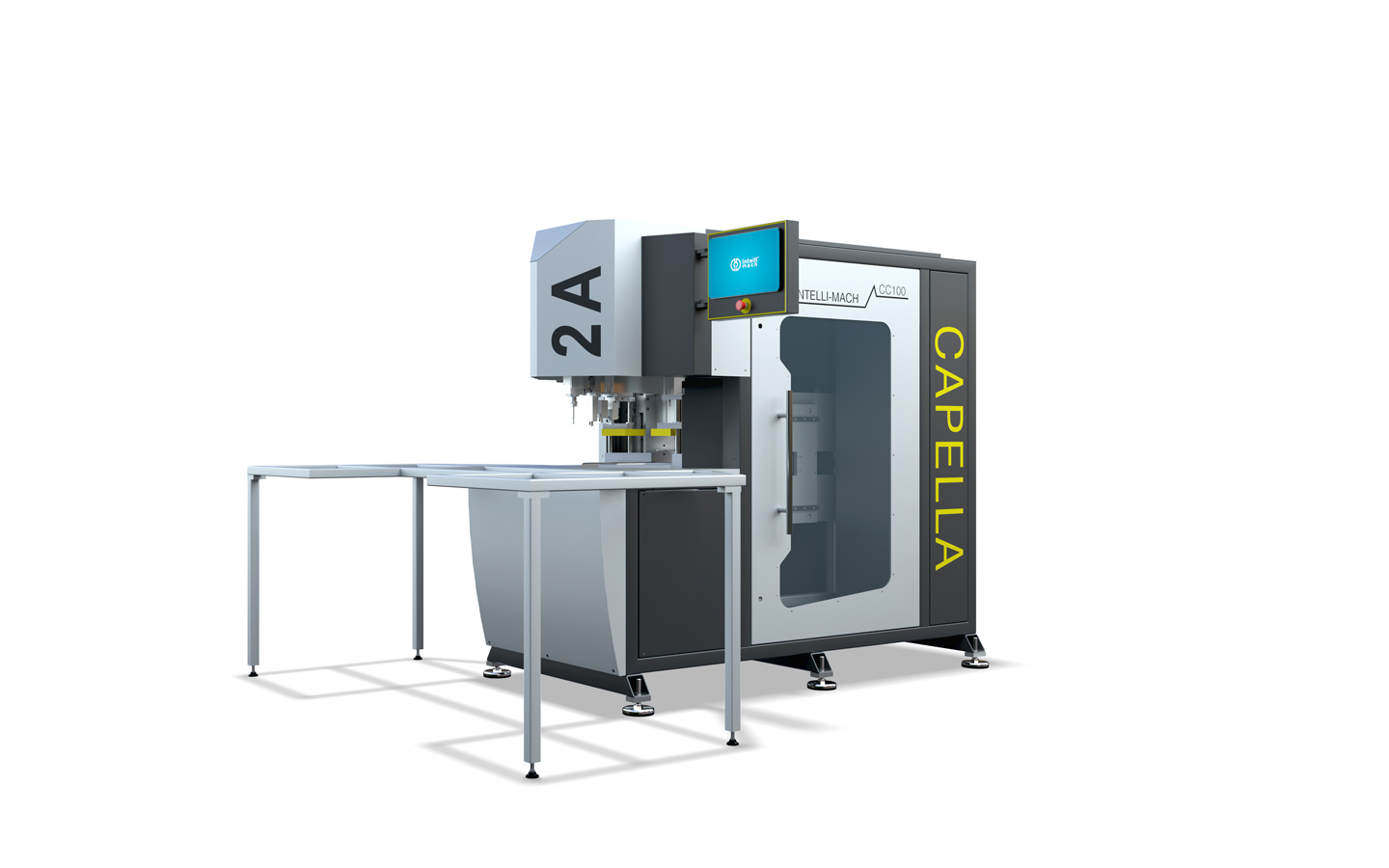

Cnc corner cleaning machine

cnc corner cleaning machine CNC PVC Profile Corner Cleaning Machine Designed to clean the corners of PVC profiles from welding seals. CNC control system (2 axis) Touch screen panel Easy system for profile setup and programming High cleaning performance with tools operated by servo control Up & bottom gasket hole drills Up & bottom inner […]

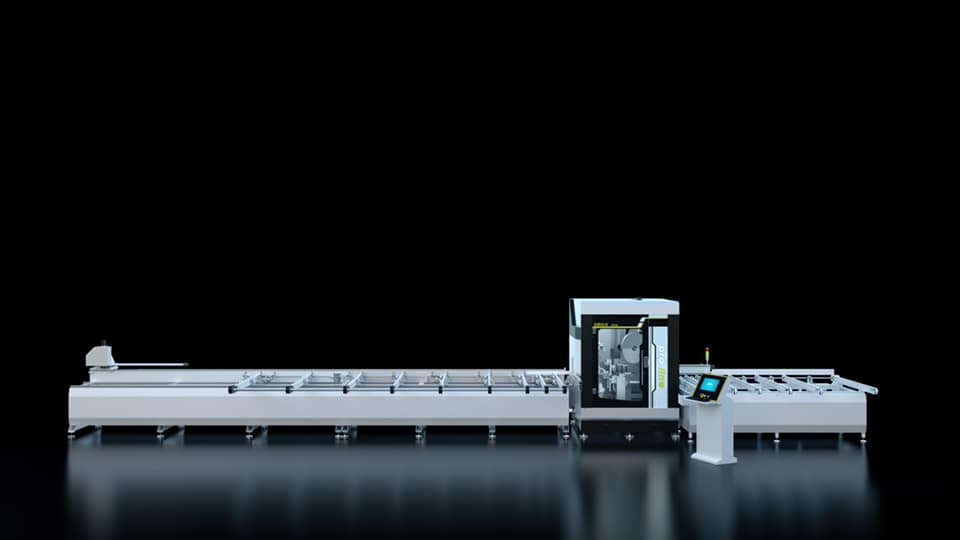

uPvc Profile cutting and drilling machinery

uPvc Profile cutting and drilling machinery pvc window door machinery,pvc mitre saws,aluminium saws,pvc welding machinery