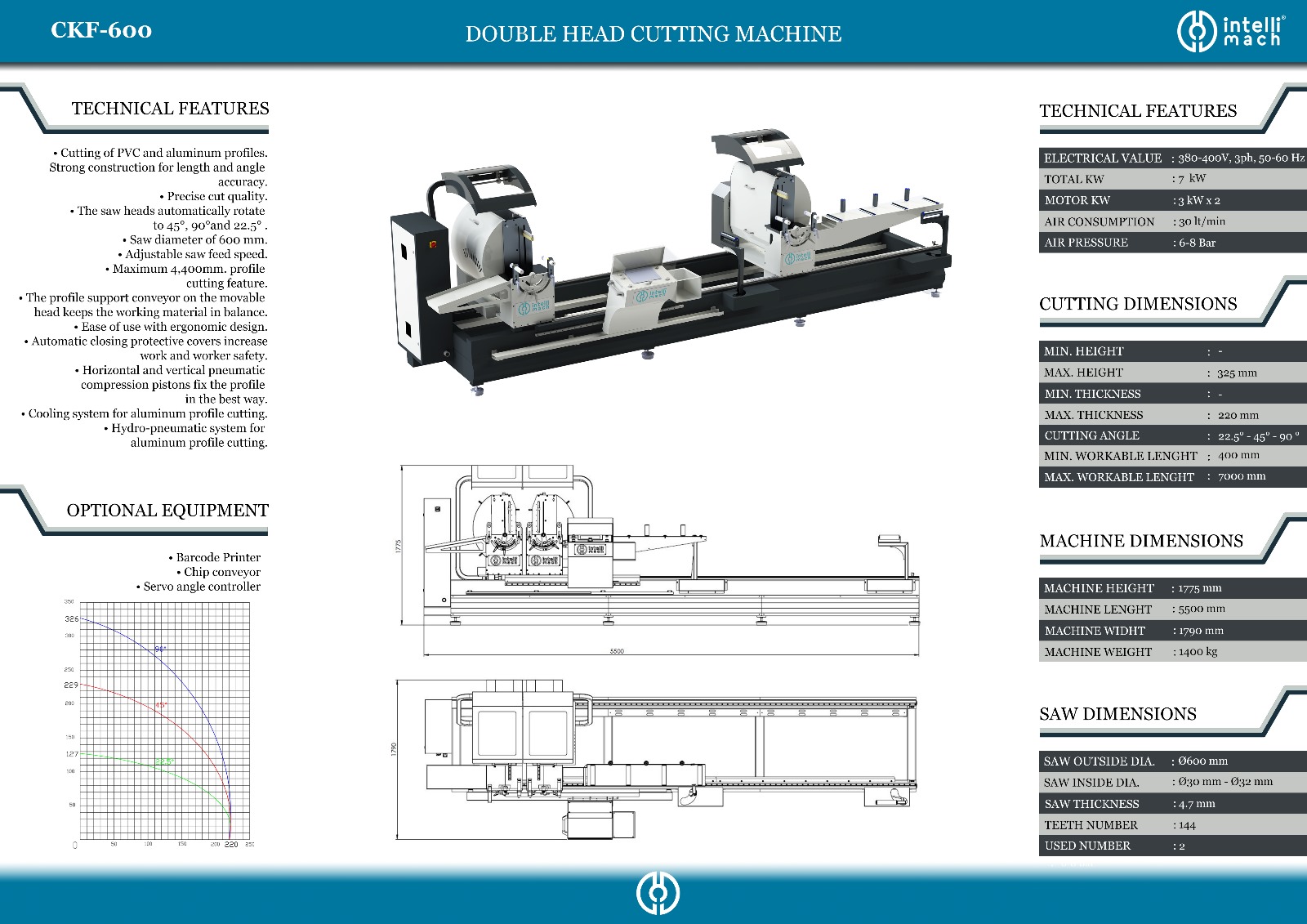

Double Head Cutting Machine 600 mm

Double head cutting is a common operation in the manufacturing and processing of PVC profiles, pipes, and other products. It involves cutting a PVC workpiece into specific lengths or angles using a machine equipped with two cutting heads. This process is widely used in the fabrication of PVC windows, doors, pipes, and other extruded profiles. Here’s a basic overview of double head cutting for PVC:

Machine Setup: Double head cutting machines are specially designed for cutting PVC profiles accurately and efficiently. These machines typically have two cutting heads that can move independently or simultaneously, depending on the specific requirements of the cut.

Measurement and Marking: Before cutting, the PVC workpiece is typically measured and marked to ensure precise dimensions and angles. This can be done manually by an operator or with the help of automation and measuring systems integrated into the machine.

Material Clamping: The PVC profile is securely clamped in place to prevent movement during the cutting process. Clamping mechanisms can vary depending on the machine design.

Cutting: The cutting heads, often equipped with saw blades or milling tools, are positioned to make the necessary cuts. The machine operator can input the specific dimensions and angles into the machine’s control system. The cutting heads then move into position and make the cuts with precision.

Waste Management: After cutting, there may be leftover PVC material, known as scrap or waste. This material is typically collected and disposed of properly.

Quality Control: After the cutting process, quality control checks may be performed to ensure that the cut PVC pieces meet the required specifications. This can include checking for accurate dimensions, angles, and the absence of defects.

Unclamping and Removal: Once the cutting is complete and quality checks are passed, the PVC pieces are unclamped and removed from the machine. They are then ready for further processing or assembly.

Double head cutting machines for PVC are essential tools in the PVC manufacturing industry because they allow for efficient and accurate cutting of profiles, which is crucial for maintaining product quality and consistency. These machines can be manually operated or fully automated, depending on the production requirements and budget of the manufacturer.