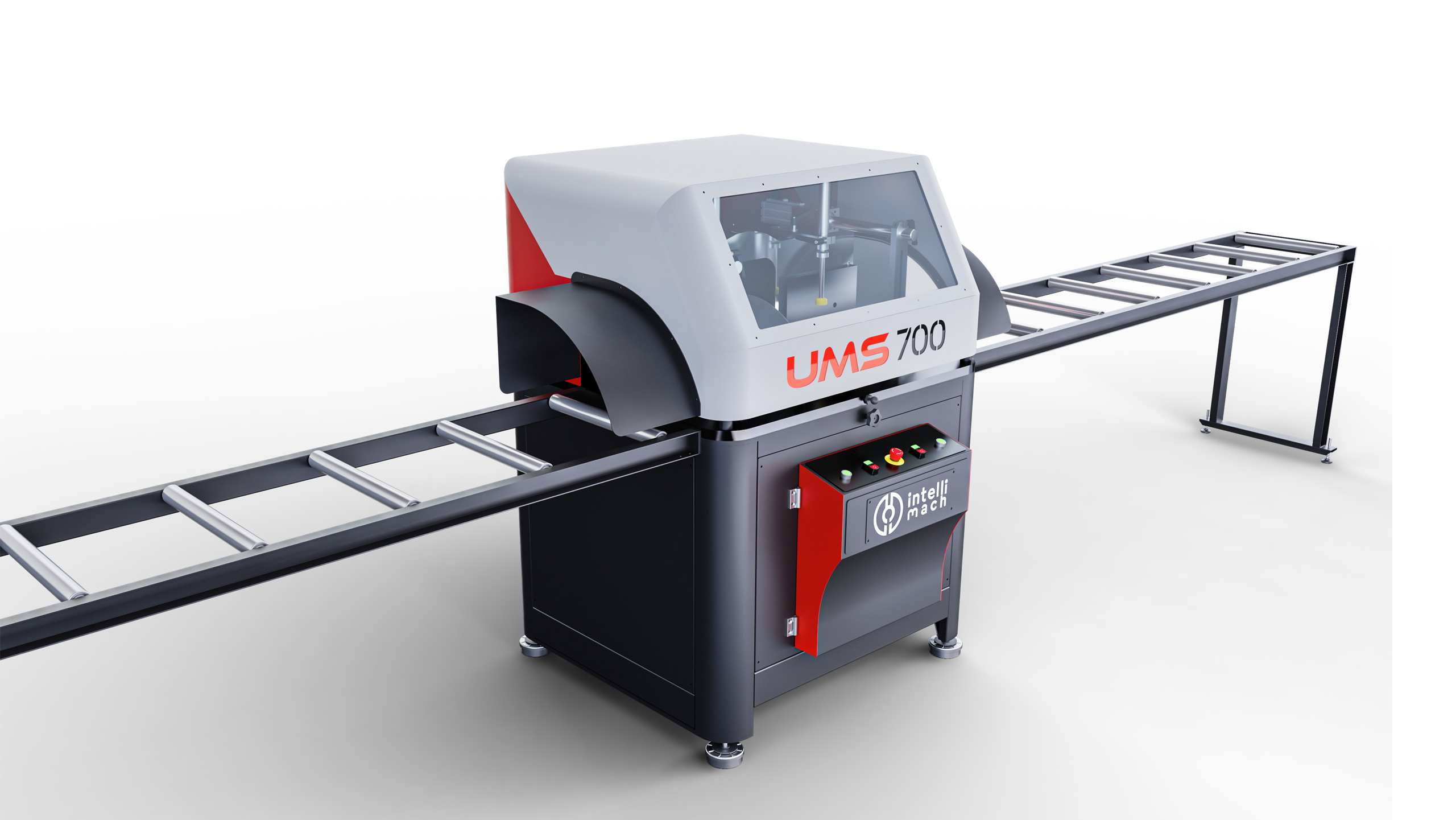

upvc welding machine

A uPVC welding machine, also known as a uPVC welder or uPVC welding equipment, is a specialized tool used in the fabrication and assembly of uPVC (unplasticized polyvinyl chloride) profiles, particularly in the production of uPVC doors and windows. The welding process is crucial for joining uPVC sections together, creating strong and durable connections. Here are key points about uPVC welding machines:

- Principle of Operation:

- uPVC welding machines utilize a process known as heat welding or fusion welding. In this process, the two uPVC surfaces to be joined are heated to a melting point, and then they are pressed together to form a solid weld as the material cools and solidifies.

- Types of uPVC Welding Machines:

- There are various types of uPVC welding machines, and the choice depends on the specific requirements of the fabrication process. Common types include:

- Hot Plate Welding Machines: These use a heated plate to melt the uPVC surfaces.

- V-Cutting Machines: These machines prepare the uPVC profiles by creating V-shaped grooves before welding.

- Corner Cleaning Machines: These machines clean and prepare the corners of uPVC profiles for welding.

- There are various types of uPVC welding machines, and the choice depends on the specific requirements of the fabrication process. Common types include:

- Features and Capabilities:

- uPVC welding machines may have features such as adjustable temperature settings, pressure controls, and precision guides to ensure accurate and reliable welding.

- Profile Welding:

- The welding process is crucial for joining uPVC profiles accurately. It is commonly used in the fabrication of frames for doors and windows, ensuring a strong and weather-resistant connection at the corners.

- Automation:

- Some uPVC welding machines are equipped with automation features, including CNC (computer numerical control) systems. Automation can enhance efficiency and accuracy in the welding process, especially in high-volume production.

- Cleaning and Finishing:

- Certain uPVC welding machines may include features for cleaning excess material and providing a smooth finish to the welded joints.

- Quality Control:

- The precision and strength of the weld are critical for the overall performance of uPVC doors and windows. Quality control measures may be integrated into the welding process to ensure consistency.

- Safety:

- uPVC welding machines should be operated with safety precautions, and operators typically wear appropriate protective gear. Safety features may include emergency stop buttons and protective guards.

When selecting a uPVC welding machine, it’s important to consider the specific requirements of your production process, the type of uPVC profiles being used, and the desired level of automation. Manufacturers of uPVC welding machines often provide guidelines for optimal operation and maintenance.