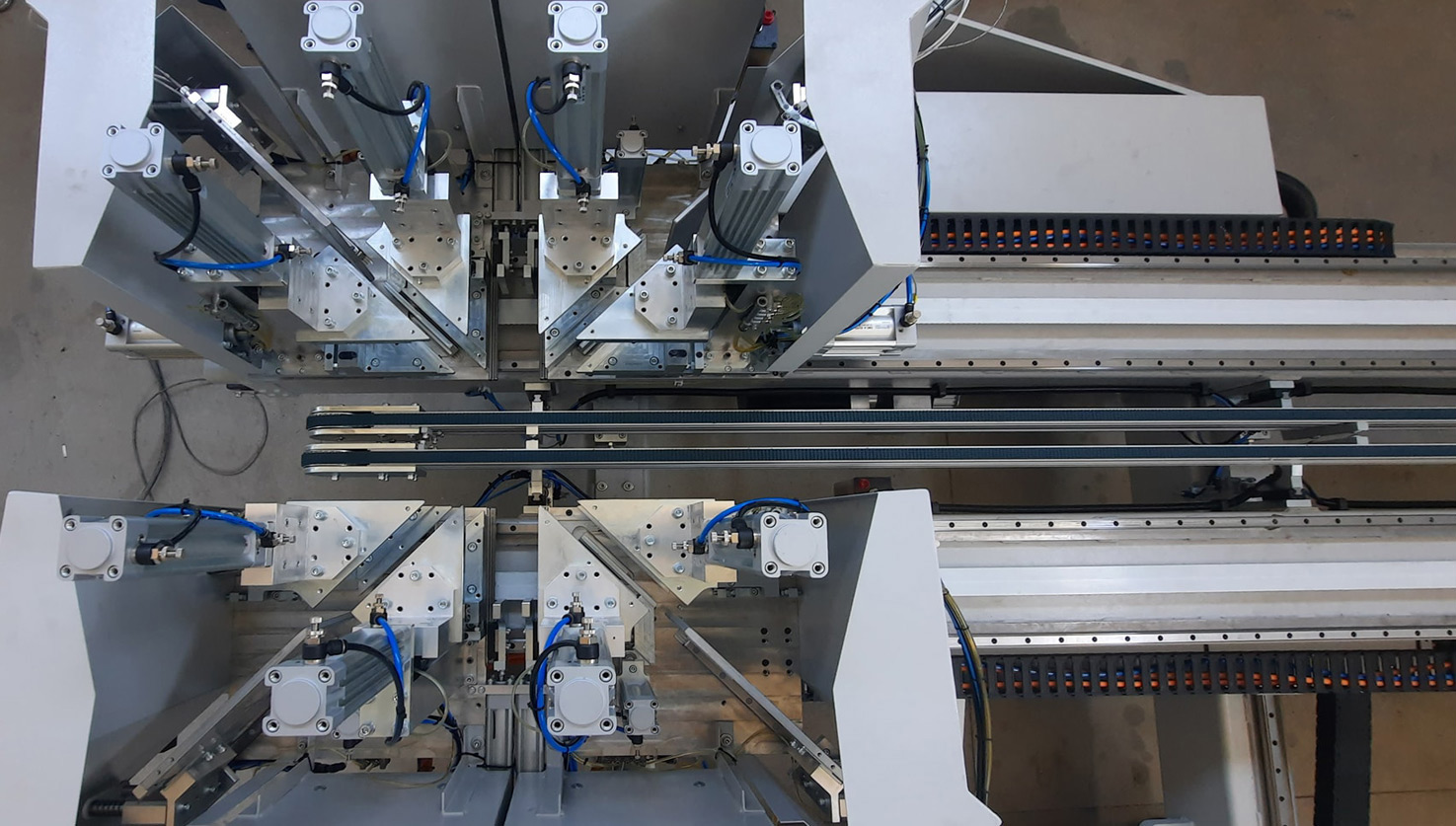

Double Head Cutting Machine 600 mm

Double Head Cutting Machine 600 mm Double head cutting is a common operation in the manufacturing and processing of PVC profiles, pipes, and other products. It involves cutting a PVC workpiece into specific lengths or angles using a machine equipped with two cutting heads. This process is widely used in the fabrication of PVC […]

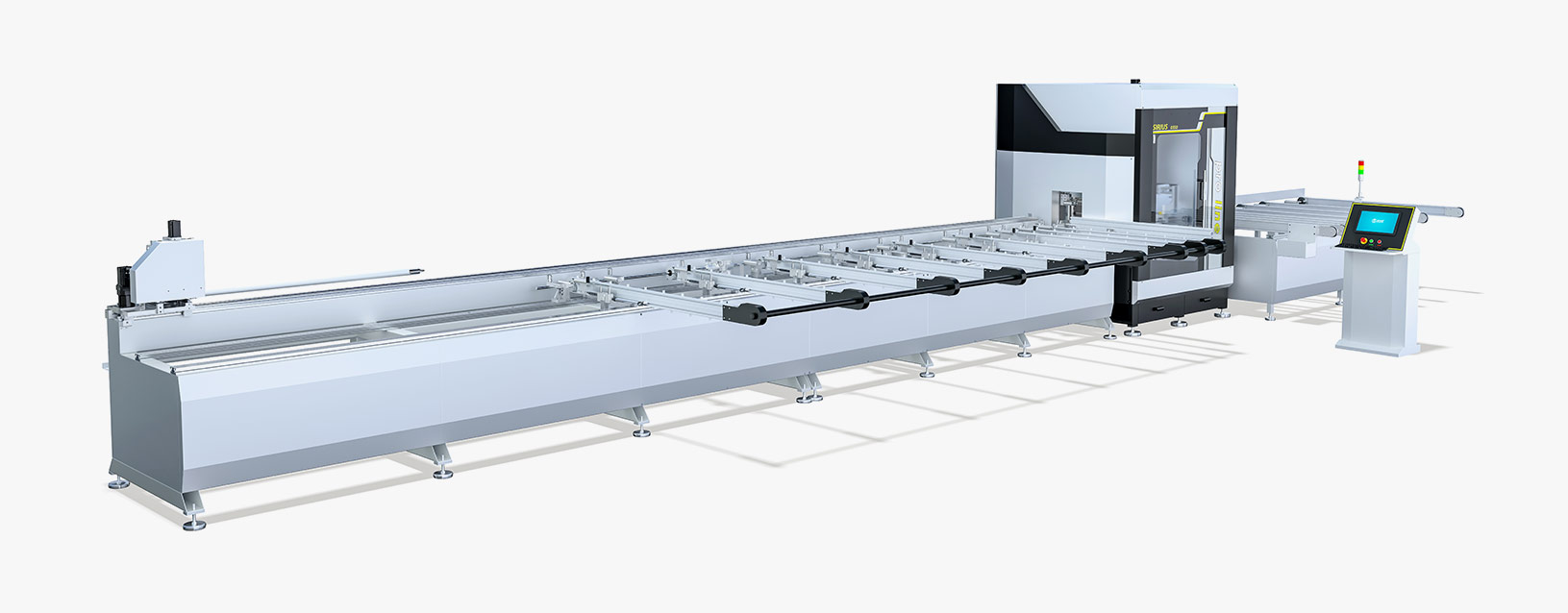

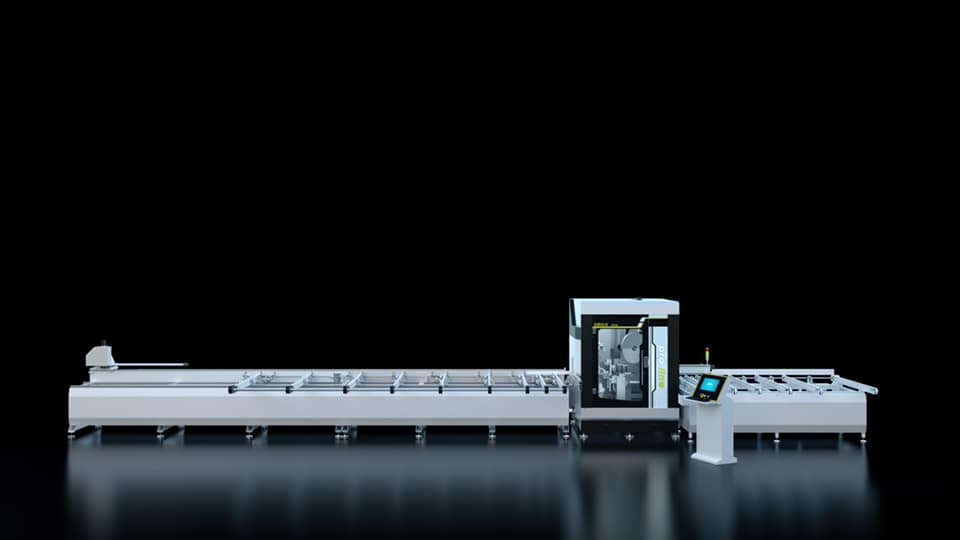

Pvc Profile Machining and Cutting Center

Pvc Profile Machining andCutting Center Sirius D550 All sawing, milling, drilling and marking operations on PVC profiles are gathered in one machine controlled by a computer. Control Panel -Automatic cutting in all angles between 30° and 150° with accuracy of 0,1° by means of servo motors -Stacking of 10 profiles (max 7 m length) -Industrial PC with Windows XP embedded […]

Pvc Window Machinery

Pvc Window Machinery window door machinery #windowmachines #cnccornercleaningmachine

Pvc Cnc Machining centre

Pvc Cnc Machining centre

Mitre Saw 400 mm

Mitre Saw 400 mm Suitable for high-volume cutting of aluminium profiles for window manufacturing and industrial applications Material infeed (cycling) protects the surface of the workpiece by means of a single-stage profile lifting system One, two or three-stroke feed can be selected using a selector switch

Aluminium Window Machinery

Aluminium Window Machinery PVC Profile Processing Machine, Aluminium,Windows & Doors Machinery ,Glass machinery SPINDLE COPY ROUTER Routing of door handle holes, lock cylinders and drain slots on PVC and aluminum profiles. Ersatile for many applications in aluminium and PVC profile machining Precision routing with a minimum of effort and easy, two-lever operation Copy routing at […]

uPvc Profile cutting and drilling machinery

uPvc Profile cutting and drilling machinery pvc window door machinery,pvc mitre saws,aluminium saws,pvc welding machinery pvc profile cnc machining , pvc cnc machining centre, Profile Machining and Cutting Center