» Products » PVC Welding and Cleaning Center

PVC welding and cleaning center

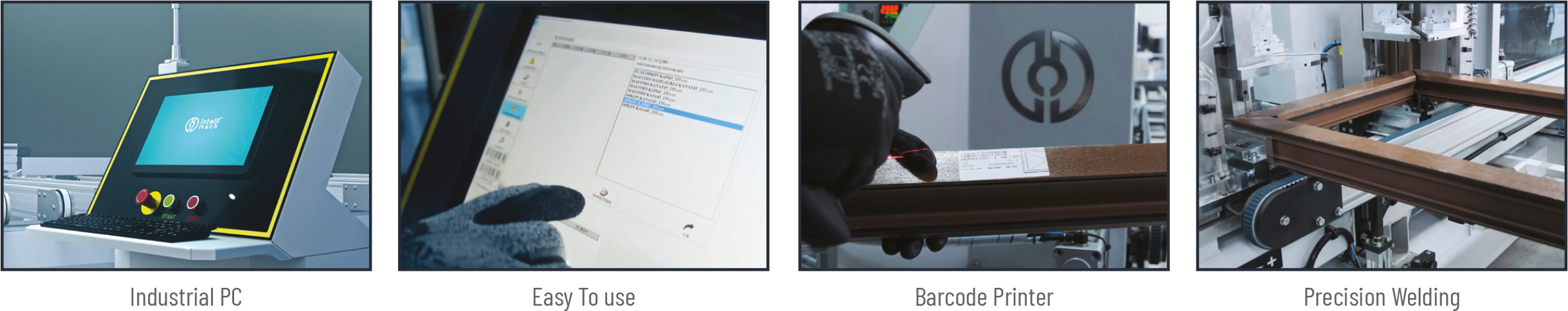

Intel Makina’s PVC Welding and Cleaning Center Four Corner Welding and CNC Corner Cleaning Automation Line Four Corner Welding Machine is formed by the integration of Cooling and Holding Station, Robotic Turning Station and CNC Corner Cleaning Machine. After the frame is welded and passed through the cooling and waiting station, turning all the corners

with the robotic turning system and cleaning all the slags formed during welding, controlling all the stages with the computer system.

WELDING

It welds the four corners of PVC Profiles at 90° angle at the same time and with high precision. In

automatic generation mode, the window works in accordance with the data received from the drawing program.

It has a computer-controlled (PID) heat control system in order to obtain welding strength within the standards.

For each profile type, there is a separately definable temperature, melting and bonding time. It

distributes the heat homogeneously to the long-lasting heating plate system, with its unique design, without

being affected by the working environment. The preheated welding blades ensure good welding even in cold

weather conditions. Welding molds can be changed quickly and easily. Axes are servo motor controlled.

COOLING AND BUFFER STATION

Works between a corner cleaner and

a welding machine.

TURNING STATIONS WITH THE ROBOTIC ARMS

High speed and high accuracy turning operation via a robotic system with strong and fast mechanical turning arms.

CNC PVC PROFILE CORNER CLEANING MACHINE

Designed to clean the corners of

PVC profiles from welding seals.

There is no information about standard equipment. Please contact us for your requests.

There is no information about optional equipment Please contact us for your requests.

© 2024. All rights reserved. Intel Makina A.S. Design: Elnur Ahmadov